Sequencing and Assembly

Our Sequencing and Assembly competence centre ensures the production-synchronous provision of individual parts and paves the way for fast and transparecostsnt processes. The use of our IT-supported delivery (just-in-sequence logistics) also minimises storage and logistics. At the same time, the creation of different sequencing variants allows our clients to optimise batch sizes in production.

OUR RANGE OF SERVICES IN THE FIELD OF FACTORY LOGISTICS

From pre-assembly and assembly to value-adding production activities – our portfolio as an outsourcing service provider in the field of sequencing is comprehensive. Regardless of the implementation version, every flow of goods is digitised and mapped as an information flow. We always use our own software motus for this purpose. In this way, we create the flexibility that enables our clients to deploy their own specialists in a targeted manner within their core competencies and thus achieve increased added value.

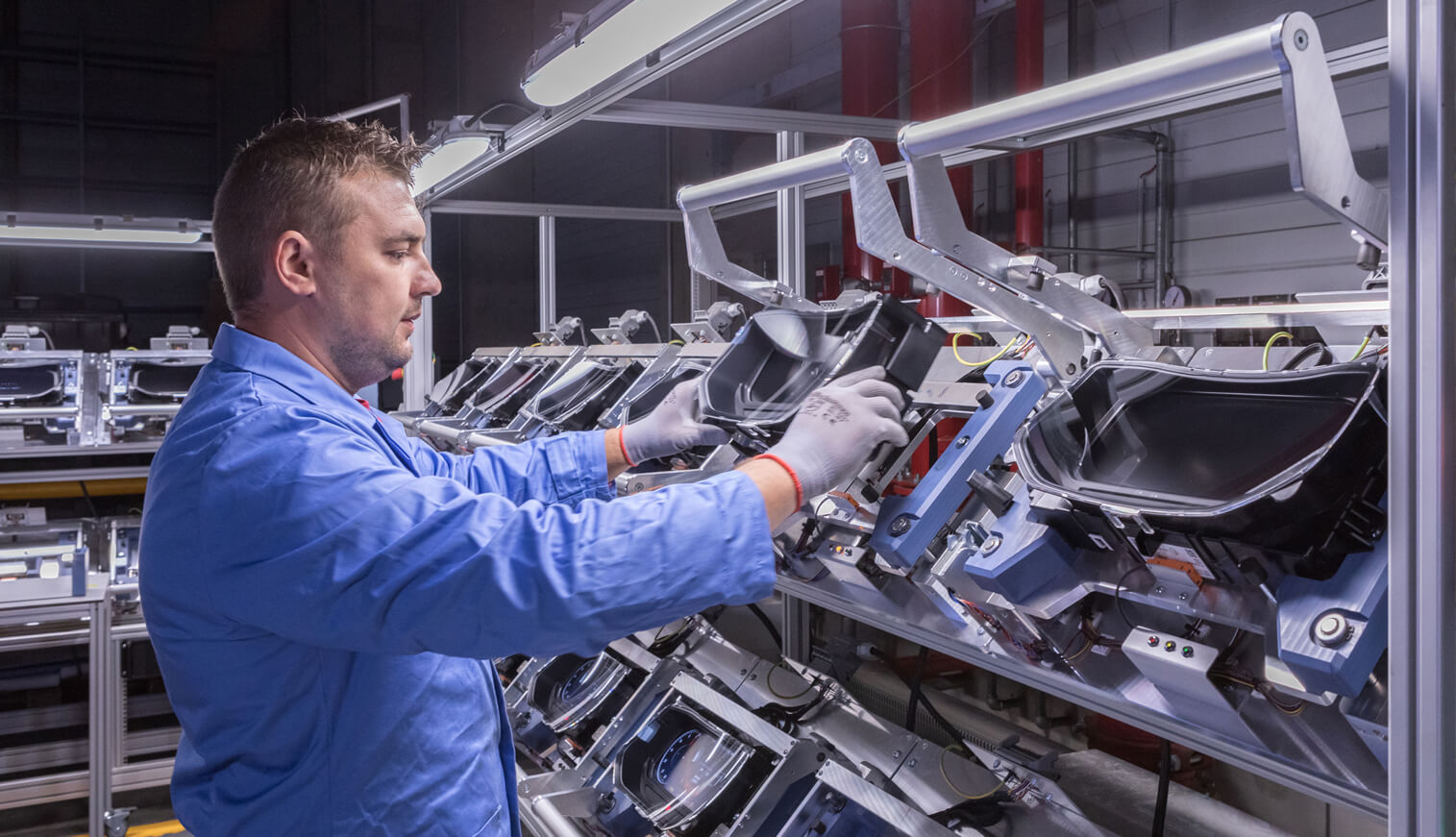

INSIGHTS INTO OUR SEQUENCING CENTRES

We have been using our expertise and experience in just-in-sequence logistics for a Bavarian car manufacturer in the premium segment since 2013.

In the automotive sector: Insights into one of our sequencing centres

JUST-IN-SEQUENCE-LOGISTICS

In the automotive logistics sector, in particular, there is often very little time between sequence retrieval to production-synchronous delivery to the assembly site. Thanks to our many years of experience in just-in-sequence logistics for various car manufacturers, our clients can rely on holistic sequencing solutions. We not only manufacture and assemble the components, but also reliably deliver them directly to the assembly line in the correct sequence. In the correct product and delivery quality, of course. In cooperation with our Transport Logistics competence centre, we ensure that even complex production chains function smoothly.

ALL SERVICES AT A GLANCE

- Parts sequencing according to the delivery schedule

- Just-in-sequence logistics: Delivery directly to production

- Creation of variants

- Assembly and pre-production, e.g. welding of exhaust systems, assembly of seat mechanisms

- Product and delivery quality responsibility

- Modern measurement methods and systems

- Sequencing software powered by motus

LOGISTICS-SOFTWARE MOTUS

»Our in-house logistics software motus warehouse maps all relevant processes digitally. The software is individually tailored to the requirements of our clients but can still be implemented quickly and easily. This ensures more transparency in the sequencing and enables us to continuously optimise the process landscape for everyone involved. An impressive example of future-proofing made by REICHHART

In the newsroom, you will find selected sample projects from our Sequencing and Assembly competence centre as well as further information about our service portfolio in the fields of transport logistics, warehousing, factory logistics and Logistics 4.0.

JOIN US AS A LOGISTICS SPECIALIST

Do you already have experience in logistics or are you looking for a challenge in a new field? If you have an eye for details and a precise working method, you have come to the right place. We are always looking for new talents to strengthen our team.

YOUR CONTACT PERSON

Would you like to learn more about our service portfolio, request an individual offer or make an appointment with us? We are happy to answer any questions you may have.

Martin Sutara

Head of Business Development

E-Mail: vertrieb@reichhart.eu